Manufacturing torque converters, a transmission component requiring high precision and durability

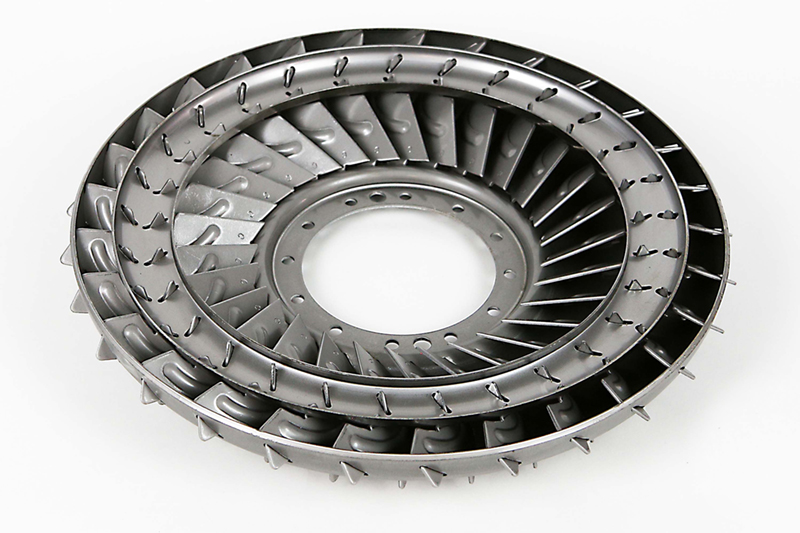

The torque converter is a key component in automatic transmissions that amplifies and transmits torque from the engine, thereby influencing fuel efficiency and driving comfort. The torque converter converts oil flow into power through the pump impeller, turbine rotor and stator blades, and is a component that requires high precision and durability.

KANAE KOGYO maintains a high production system and high quality. We manufacture torque converters by refining our production technology and making full use of our patented technology.

Manufacturing Process

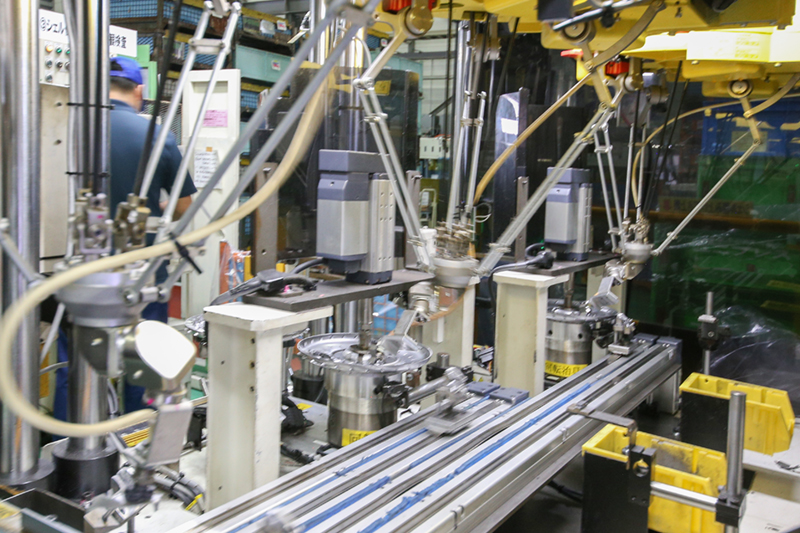

KANAE KOGYO carries out integrated production from stamping, cutting, assembly, brazing and quality measurement of parts.

Impeller

Turbine

Technique, manufacturing and quality

We operate in a factory that combines NC, robotics and other equipment to save labour and improve efficiency. We contribute to the quality of our customers' products by applying our unique technology.

Monthly Production Volume

| Product | Monthly production volume | Number of items produced | Additional |

|---|---|---|---|

| Torque converters | 128,000 | 40 |

(Results November 2018)